With the rapidly increasing market share of electric vehicles, the demand for better batteries has never been stronger. Headlines from the battery industry often suggest that a step-change in electric vehicle performance is just around the corner: 10 minute charge times, 1000 km range, improved safety, and all at reduced cost without the need for exotic materials. Based on the premise that patent filings are an indication of the maturity of a technology, we’ve taken a look at patent filing statistics in an attempt to gain some insight into what the industry is really up to, and gauge how close we are to adopting next-generation battery technology.

In part 1 of this two-part series, we will look at core chemistry and electrolytes. Part 2 will focus on electrode materials.

Beyond lithium

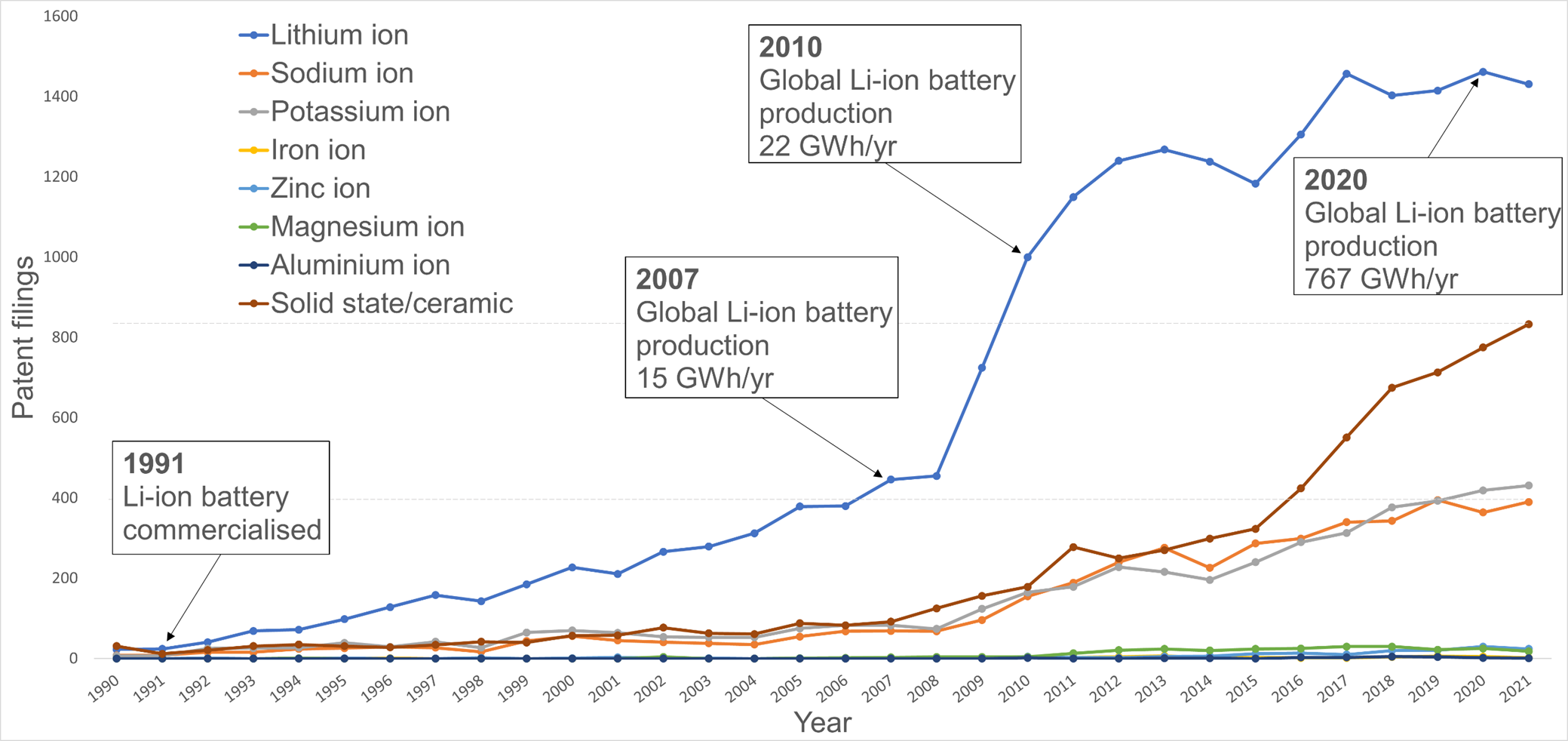

Rechargeable batteries work by shuttling charged ions between two electrodes. In almost all electric vehicles these ions are lithium ions. However, there are concerns around the cost and supply of lithium. This means the race is on to develop lithium-free batteries with comparable performance. Figure 1 compares annual patent filing statistics for batteries using different core chemistries including incumbent lithium ion technology, sodium ion technology and more speculative chemistries using metals such as zinc.1

Unsurprisingly, lithium ion filings lead the way by some margin, with sodium ion and potassium ion filings next. Global production of sodium ion batteries is touted to be 10 GWh/year in 2025, with market growth predicted to be similar to that of lithium. Our findings show that this is consistent with the trajectory and number of sodium ion patent filings, since global lithium ion battery production capacity reached 15 GWh/year soon after lithium ion filings reached the level of current sodium ion filings. Perhaps unexpectedly, since sodium ion batteries are often described as the main challenger to lithium, our findings suggest that potassium ion technology is on par with sodium ion technology and will fight it out with sodium to see which will be the preferred alternative to lithium.

In comparison, filings for other charge carrier chemistries (iron, zinc, magnesium and aluminium) are languishing. Of these, zinc ion and magnesium ion technology have the most activity but may not be suitable for commercialisation in the near future, based on filing numbers as an indicator of market readiness.

Solid-state batteries

The vast majority of lithium ion batteries currently use a liquid electrolyte as the medium through which lithium ions move between electrodes. Replacing liquid electrolytes with solid electrolytes has the potential to enable the use of more energy dense electrode materials and improve safety and cycling performance. Figure 1 also shows filing numbers for solid-state batteries, which have made the boldest claims in terms of imminent improvements in capacity and charge time. This is consistent with our data, which, based on historical data for lithium ion batteries, suggests that filing numbers are at the levels expected for mass adoption, with solid-state batteries having been forecast to exceed a rate of production of 2 GWh/year in 2023.

Conclusion

Our findings provide data to support the notion that sodium ion and solid-state batteries are on track to become a significant portion of global battery capacity within the next five years. In contrast, charge-carrier chemistries other than lithium, sodium and potassium are quite a distance behind these leaders if you take patent filings as an indicator.

Keep an eye out for the second part of this series, in which we will look at cathode materials and metal-anode battery technologies which promise to solve the sustainability and range limitations of current technologies.

If you would like to contact Nico Cousens to discuss your thoughts on batteries and cleantech, please don’t hesitate to reach out to him.

1 Search strategy: limited to claims only; search string for each technology includes “battery” or "electrochemical cell"; limited to Cooperative Patent Classification H01M (“PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY”); limited to PCT, European and US filings; complete data for filings beyond 2021 unavailable at time of search due to 18 month publication delay for patent applications.